Toyotism is an industrial production model developed in Japan in the second half of the 20th century. Developed by engineer Taiichi Ohno and Eiji Toyoda, Toyotism adapted to the spatial and Japanese socioeconomic situation of the period, and was initially implemented in a Toyota factory in the 1970.

It is characterized by the absence of stocks, production flexibility and the pace of production that follows the demand for the product, a system that became known as just in time. The achievement of positive results led to Toyotism being widely adopted around the world, and it is still a model widely used in companies today.

Read too:Third Industrial Revolution — the improvement of techniques in the field of industry

Summary about Toyotism

Toyotism is an industrial production model developed in Japan in the second half of the 20th century. It is also called a flexible production model.

It was first implemented at one of Toyota's factories in the 1970s.

The absence of stocks of raw materials and goods, the flexibility of work, the presence of multitasking workers and production according to demand (

just in time) are the main characteristics of Toyotism.Its advantage is greater production efficiency and reduced inventory maintenance costs, in addition to the adoption of technological innovations in the production process.

The reduction in jobs within factories and structural unemployment are the disadvantages of Toyotism.

Video lesson on Toyotism

What is Toyotism?

Toyotism is a developed industrial production model and implemented in Japan in the second half of the 20th century and which has gained more and more space in industries around the world. It received this name because it was first adopted in one of the factories of the vehicle manufacturer Toyota, a famous Japanese transnational company.

A creation of Toyotism is attributed to engineer Taiichi Ohno (1912–1990), who worked at Toyota for part of his life. Due to its main characteristics, which we will learn about below, Toyotism can also be called a flexible production model.

Main characteristics of Toyotism

Toyotism is known for its great flexibility in the production process and work organization. Japanese production logic emerged at a time of great technological advancement in the world, which characterizes the recent phase of globalization, which led to the adoption of modern machinery and advanced production techniques within factories and vehicle assembly plants.

Greater global connection between different territories and the rapid growth of presence of transnational companies in all regions of the planet still marked what we call vertical disintegration of production, characteristic of Toyotism. This means, for example, that a vehicle was not necessarily produced in just one factory. While one unit developed its parts, another industry, which could be located in a different location, was responsible for developing the engine, the other manufactured the tires, and a fourth company was in charge of assembly Final.

Another striking characteristic of Toyotism is the lack of stocks. Unlike Taylorism and Fordism, in the Toyota model, production is carried out according to the demand for a certain product. In this system, production is done in different batches.

Not even the raw materials They are stored, but rather acquired in the right quantity that current production requires. For this to happen, there was great coordination between input suppliers, factories and consumers.|1| O system of absence of stocks and prompt fulfillment of demand became known as just in time, which means “at the right time”.

In Toyotism, the workers perform different functions, which occurs depending on the progress of production. As a result, the same employee can perform different tasks within factories, which demands greater qualifications from the professional and, at the same time, reduces the required workforce.

Read too: Characteristics of Brazilian industrial space

Origin of Toyotism

O Toyota model emerged from the exhaustion of Fordism in the socioeconomic context of Japan in the 1950s, which corresponds to the post-Second World War. It was during this period that mechanical engineer Taiichi Ohno (1912–1990) became a production specialist at Toyota, a factory where he had worked for almost two decades.

Also in the 1950s, Eiji Toyoda (1913–2013), an engineer who became president of Toyota shortly afterwards, visited Ford's factories in Detroit, in the United States, and realized the need to change the production model for the Japanese reality.

Japan is an island country with a small territorial extension, largely dependent on the import of finished products and inputs for production. Furthermore, its population is smaller than that of the United States, which means a reduced consumer market. You large stocks characteristic of Fordism were not suitable for this context. Thus, Ohno and Toyoda collaborated in the elaboration of the Toyotist logic of production, also known as just in time.

The implementation of this new industrial production model took place in the 1970s, and its effects were very positive in terms of the company's productivity and profits. As a result, Toyotism began to be adopted in other companies around the world.

Changes caused by Toyotism

Toyotism introduced important innovations in industrial production and work, many of which are still used today in companies and factories around the world. Look the main changes caused by the Toyota model:

end of large stocks;

immediate fulfillment of demand through batch production;

multifunctional workers;

incorporation of technology throughout the production process;

quality control at all stages of production.

Advantages and disadvantages of Toyotism

To the advantages of the Toyota model They are linked to the production process and the marketing of final products. Are they:

reduction of production costs with the end of stocks and greater integration between production chains, production itself and demand;

adapting products to consumer needs, with great customization capacity and a diverse range of goods;

high quality products due to the strict control carried out throughout the process;

greater productivity and production efficiency, reducing input waste;

greater number of qualified workers capable of performing various functions.

To the disadvantages of Toyotism fall, for the most part, on labor:

increase in unemployment caused by the reduction of jobs within factories, which leads to an increase in informal work;

structural unemployment generated by the use of new technologies in production;

greater outsourcing of work and production;

need for constant acquisition of raw materials and inputs.

What are the differences between Toyotism, Fordism and Taylorism?

The following comparative table indicates the main differences between Toyotism and the two production models before it: Taylorism, dating from the 19th century, and Fordism, developed in the first half of the 19th century XX.

Toyotism |

Fordism |

Taylorism |

Lack of stocks. |

Stock formation. |

Stock formation. |

Work follows the pace of demand. |

Work follows the rhythm of the production conveyor present on the assembly line. |

Work imposed vertically and according to the employee's income. |

Batch production. |

Mass production. |

Mass production. |

Multitasking workers, able to perform different functions. |

Specialized and active workers in a single role. |

Workers working in a single function or task. |

Quality control carried out during all stages of production. |

Quality control carried out at the end of production. |

Quality control carried out at the end of production. |

Solved exercises on Toyotism

Question 1

(Enem 2020) “Toyotism, from the 1970s onwards, had a great impact on the Western world, when showed advanced countries as a possible option for overcoming a crisis of accumulation."

(ANTUNES, R. The meanings of work: essay on the affirmation and denial of work. São Paulo: Boitempo. 2009. Adapted.)

The organizational characteristic of the model in question, required in the crisis context, was the (a)

a) expansion of large stocks.

b) increase in mass manufacturing.

c) adequacy of production to demand.

d) increased mechanization of work.

e) centralization of planning stages.

Resolution: Alternative C.

The adequacy of production to demand is the main characteristic of Toyotism and the aspect that differentiates this model from its predecessors.

Question 2

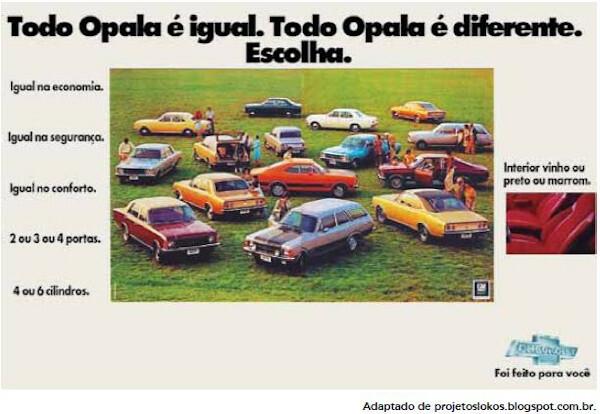

(Uerj 2015) In the 1970s, the predominant productive model in Brazilian capitalism was Fordist. However, in the advertising broadcast in 1977, it is possible to identify the transition to the subsequent production model.

From the advertisement, it can be seen that this new model is characterized by the introduction of:

a) mass consumption

b) assembly line

c) manufacturing on demand

d) production with flexibility

Resolution: Alternative D.

The advertisement shows greater flexibility in production, a characteristic that is typical of the Toyotist model, successor to Fordism.

Grades

|1| LUCCI, Elian Alabi. Territory and society in the globalized world, 2: secondary education. São Paulo: Saraiva, 2016, 3 ed., 289p.

Image credits

[1] ChameleonsEye / Shutterstock