Simply delicious. A statement that goes very well with the condensed milk, an industrialized product used in several dessert recipes (pudding, mousse, brigadeiro, pies, pave, cakes, sweets, donuts, etc). Even though it is very present in people's daily lives, many do not know how its processing is carried out.

The pudding is an example of a dessert made from condensed milk

What is condensed milk?

Despite the term condensed in the name, condensation (the passage of a gas to a liquid state through the release of heat, an exothermic phenomenon) is not used at all during the processing of condensed milk. In fact, vaporization is used (the passage of a liquid to a gaseous state through the absorption of heat, an endothermic phenomenon).

Therefore, the question remains: why was the product not called steamed milk? This did not happen because steamed milk already exists on the market, which is milk with a lower amount of water, just like condensed milk, but which does not receive the addition of any other substance, such as sugar.

Condensed milk processing

The industrial processing of condensed milk follows a standardized sequence, which involves centrifuging, filtering, pasteurizing, adding sugar, steaming and adding lactose.

During the production of condensed milk, 60% of the water content of whole cow's milk is removed and then some substances are added to it with the function of stabilizing, sweetening and homogenize it.

Condensed milk processing steps

Initially, the whole milk (from cow) is placed inside a centrifuge (equipment that makes the milk rotate through 360 degrees). During centrifugation, the impurities present in the milk, which have greater density, are moved to the bottom of the centrifuge more quickly.

Centrifuge: equipment used to decant milk impurities

Then, the centrifuged whole milk is subjected to a filtration process to remove impurities that were not decanted. All these impurities are retained in the filter (which can be paper or nylon).

Do not stop now... There's more after the advertising ;)

After filtration, the milk is placed in a pasteurizer. During this process, the milk is heated to 75 OC and then cooled to a temperature of 20 OÇ.

The objective of pasteurization is to eliminate possible microorganisms (fungi, bacteria, etc.) arising, for example, from poor cow hygiene or poor storage.

4The Step: Adding sugar

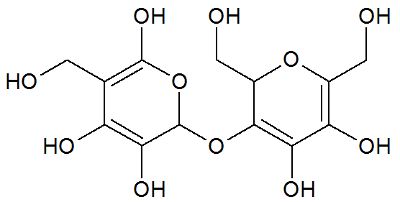

Right after pasteurization, the milk receives the addition of sucrose (sugar). The amount of sucrose added is around 170 g to 180 g for each liter of milk. Thus, the sucrose concentration in condensed milk is 64.5%.

Structural formula of sucrose

Then, the sweetened milk is placed inside a device called a rotaevaporator, which is able to promote dehydration (loss of water) without the need for an exaggerated increase in temperature.

At this stage, the milk is heated to 65OC approximately for a period of 10 minutes until 60% of its entire volume of water is evaporated. If we had, for example, 1 L of milk, 600 ml of its volume would be evaporated.

6The Step: Addition of lactose

Finally, 0.02% lactose powder is added to the remaining material after spraying. The addition of this amount of lactose is to prevent sugar crystals from getting big enough to be noticed when we ingest the product.

Lactose structural formula

A little history of condensed milk

For some historians, condensed milk was discovered in the year 1853, when the American farmer Gail Borden Junior created it in an attempt to produce a milk that could be packaged and transported and that maintained the ideal conditions for consumption human.

For other historians, the recipe for condensed milk was made by Napoleon Bonaparte's cook, who developed after being tasked with finding a way for soldiers to transport milk during the wars.

By Me. Diogo Lopes Dias