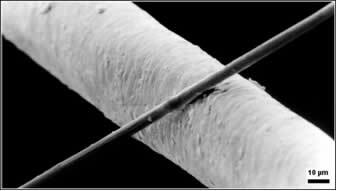

Carbon fibers are filamentous composites made up of more than 90% carbon and filaments from 5 to 15 µm in diameter.. A composite is formed by joining certain non-soluble materials together to form a better quality product than the originals. The fibers are joined together by a polymer called matrix (resin), which works as a kind of glue, which binds the fibers in the form of threads, gives shape to the material and distributes the force inside the set.

Comparison of hair (from upper left to lower right) with carbon fiber[1]

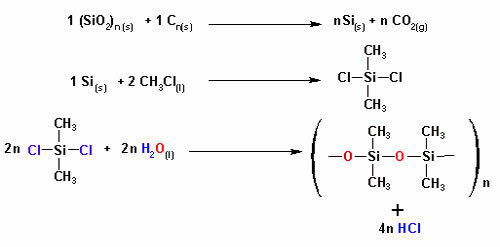

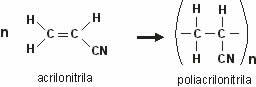

The manufacture of carbon fibers is usually carried out through the pyrolysis controlled plastic fibers, that is, these fibers are subjected to high temperatures (above 800 ºC), and this material is decomposed and converted into a solid carbonaceous material. The material most currently used for the production of carbon fibers is the polyacrylonitrile (PAN, also called orlon,acrylic and darlon), an addition polymer formed by successive additions of acrylonitrile monomers:

Carbon fibers can also be produced by the pyrolysis of tar or from rayon.

The first to intentionally produce carbon filaments was Thomas Edison, in 1878, through the pyrolysis of cotton, to be used in incandescent lamp filaments. However, the production of commercial carbon fibers only started in 1950, and since then much research has been done to improve the quality of this material.

Among the main properties of carbon fibers are: high tensile strength, modulus of elasticity extremely high, low specific mass, good electrical and thermal resistance, as well as chemical inertness, except for oxidation.

Since it is so strong and light at the same time, carbon fibers are a versatile material with wide application, being widely used in the manufacture of spacecraft, in structural components subjected to high temperatures, such as components of aircraft and rocket turbines, in the automobile industry, in equipment used in electroanalytical techniques, in bicycle parts, as well as in consumer goods, such as cell phones, shoes, furniture, household appliances, medical, sports and dental care.

There are more than 100 different types of carbon fibers, and for each application, you must select the most convenient one, according to its properties. Unfortunately, Brazil produces very little of this composite, the countries that most dominate in this field are Japan and Germany.

* Credits for the images:

[1]: Image taken from: Wikimedia Commons;

[2]: Author: Jordan Tan /Fonte:Shutterstock.com

By Jennifer Fogaça

Graduated in Chemistry