Plastics currently used in bags, toys, tables, household items, bottles, packaging and in the most diverse products around us are of fossil origin, that is, they are derived from Petroleum.

as shown in the text Oil Refinement, crude oil goes through a fractional distillation process in refineries and produces several fractions. Some of these fractions, in turn, go through the process of cracking in which molecules of Hydrocarbons larger ones are broken down and give rise to smaller molecules. These hydrocarbons with smaller carbon chains then undergo polymerization reactions that result in plastics.

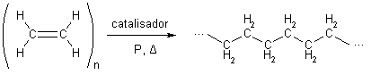

O polyethylene, for example, is a polymer resulting from the successive addition of several ethylene (or ethylene) molecules. This ethylene results mainly from the cracking of naphtha and the treatment of the natural gas, two petroleum-derived fractions.

Polymerization of ethylene to polyethylene

With high-density polyethylene (HDPE or HDPE) and low-density polyethylene (LDPE or LDPE), numerous objects are manufactured, such as water, soft drink and juice bottles; tablecloths, various types of packaging, plastic bags, bathroom curtains, plastic films, pharmaceutical and food packaging, coatings for wires, cables, tubes, toys and utensils household appliances.

High and Low Density Polyethylene Products

The problem is that this plastic is not biodegradable, that is, it is not degraded by microorganisms such as fungi and bacteria. Thus, when they are discarded, they end up remaining in the environment for decades and even centuries, further aggravating the problem of accumulation of garbage and pollution of water, soil and air.

Polymers of fossil origin are not biodegradable and generate great pollution

Furthermore, the extraction and exploitation of oil also generates pollution and environmental impacts.

Considering these problems and that it is practically impossible to think about the development of our society without the use of polymers, there is an urgent need to find alternatives to source plastics fossil.

A major advance in this regard was the production of green plastic or green polyethylene from sugarcane ethanol. Its constitution is exactly the same as common polyethylene, with the same properties, performance and application versatility. The only difference is the raw material used in its production, which, instead of being oil, is sugarcane.

Its production process, in short, is done as follows:

1- The sugarcane is harvested and taken to the mills, where it goes through the common process of alcohol production (ethanol - H3C CH2 ─ OH). This process can be seen in detail in the text Ethanol production;

Do not stop now... There's more after the advertising ;)

Sugarcane is the raw material for the production of green polyethylene

2- The alcohol produced goes through a process of dehydration to obtain the ethene;

H3C CH2 ─ OH → CH2 CH2 + H2O

This reaction is explained in the text. Intramolecular Dehydration of Alcohols.

3- The ethylene is polymerized in polyethylene production units.

4- Green polyethylene is transformed into the desired products, such as disposable diaper films, toys, vehicle fuel tanks and containers for yoghurt, milk, shampoo and detergents.

Among the main advantages of this green plastic, we can highlight:

* It is 100% recyclable;

One of the main advantages of green polyethylene is that it is completely recyclable

* Its raw material source (sugar cane) is renewable, unlike oil, which is finite;

* Does not contribute to the addition of carbon dioxide (CO2) In the atmosphere. This gas is the main cause of global warming and is produced by fossil fuels. In the case of green plastic, it can contribute to reducing global warming, given that sugarcane plantations carry out photosynthesis, absorbing CO2 the atmosphere;

* Even when incinerated, the polyethylene from sugarcane ethanol is practically neutral in relation to CO2. Thus, after being used and discarded, these plastics can be incinerated for energy generation, saving on the use of fossil fuels.

Unfortunately, green polyethylene is not biodegradable. But it can be classified as a bioplastic because, according to the definition of the European Bioplastics Association, plastics produced from renewable sources and/or biodegradable plastics are classified as bioplastics or biopolymers.

However, a problem pointed out by some is that, to produce this green plastic, it would be necessary to expand sugarcane agriculture, which could occupy land that would be used for other crops, in addition to the fact that sugarcane is already widely used for the production of alcohol and sugar. Estimates indicate that one hectare of sugarcane generates three tons of green plastic.

The first company producing this plastic was Brasken. According to the producers and experts in the case, the scenario for the production of raw material from green plastic is favorable and would not affect the production of sugar or fuel ethanol. Furthermore, it is believed that the development of new technologies will help this production process.

By Jennifer Fogaça

Graduated in Chemistry