Kanban is a term of Japanese origin and literally means "card" or "signaling".

This is a concept related to the use of cards ( sticky notes and others) to indicate the progress of production flows in serial manufacturing companies.

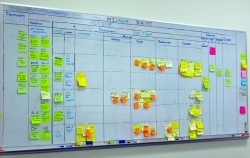

These cards contain indications about a particular task, for example, “to do”, “in progress” or “completed”.

Using a Kanban system allows for detailed production control with information on when, how much and what to produce.

The Kanban method was initially applied in Japanese serial manufacturing companies and is closely linked to the concept of “just in team”.

The Japanese car company Toyota was responsible for introducing this method due to the need to maintain an efficient functioning of the series production system.

Learn more about the meaning of Toyotism.

Electronic Kanban (e-Kanban) is used to replace the physical method, avoiding some problems such as lost cards and providing faster updating of the task board.

Currently, Kanban is often used in conjunction with Scrum as they are two methodologies used in agile software development.

Find out more about the meaning of scrum It's from kaizen.

just in time

just in time (JIT) means “at the right time”. It is a Japanese model that seeks to eliminate inventories and streamline production.

A minimum of raw material is stored in stock, only in a quantity that allows the production process to be maintained at the moment. The number of providers is also reduced for the model to work efficiently.

Learn more about the meaning of just in timeand also know thePomodoro Technique.