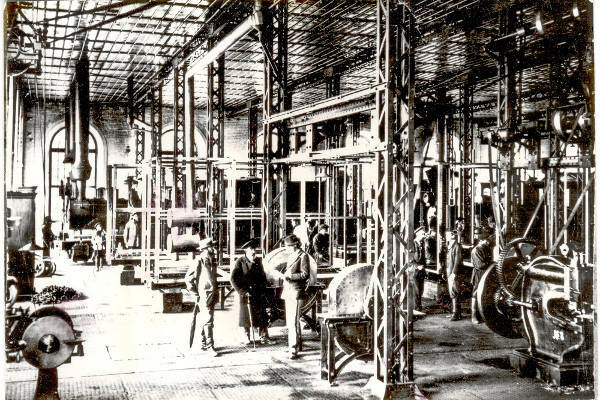

Taylorism, also known as Scientific Administration, is a way of organizing the production process created by Frederick Winslow Taylor at the end of the 19th century, amid the events of Industrial Revolution. In order to maximize production, Taylor segmented the production process, giving rise to a form of scientific administration in companies, with a new organization of work, focused on workers specialization and on management role, thus creating the so-called scientific management.

See too: Difference between Taylorism and Fordism

Who was Frederick Taylor?

Frederick Taylor was born in the United States, in March 1856, in the state of Pennsylvania. A mechanical engineer by training, Taylor worked as a worker and engineer in some companies and factories in the U.S, where he began to observe the production system and industrial administration.

Taylor found that the way work was organized did not generate profit and was therefore inefficient. From this, he began to study ways to improve the performance of each worker, as well as to seek more effective strategies regarding management, with the

objective to increase production and reduce time spent to product.

Taylorism characteristics

The main idea of Taylorism was the rationalization of work. Realizing that workers lost a lot of time during production by not mastering their role, Taylor noted that it was necessary improve functions from each to avoid slowness in production and unnecessary physical effort.

For this, it was necessary for employees to receive instructions regarding the function performed to that could improve their productive capacity and allow the maximum use of their skills. Thus, the workers started to be selected according to their aptitudes. and to receive training based on scientific methods with planned activities, optimizing work and time. Each employee would perform a specific function, thus being oblivious to the final result.

Taylor also defended that the administration should be attentive to the issue of wage improvement, reduced working hours, bonuses through what was produced by each worker and also the use of methods to reduce the fatigue of the employees, avoiding unnecessary movements, which would lead to both the prosperity of the employee and the employer.

In this context, it became essential to management effectiveness. For Taylor, workers should be supervised in order to avoid idle time, as well as time wasted with unnecessary executions of the functions performed. The role of management was essential for the proper functioning of the production process, making clear the hierarchy and roles of each within the organizational model.

Management should administer and supervise the execution of the work through established rules and standardized methods, as well as plan production, always looking for the best possible productivity in less time and with less expense. With this, a division was established in the production processes: those who perform the work, but who do not study the processes carried out, and those who analyze the work according to studies and methods scientific.

It was up to the manager to also provide the worker with the necessary means so that the work could be carried out, as well as the improvements of each function and also the incentives for the work to be done in the best way. During the journey, it was up to the management to set deadlines for the delivery of the produced goods, schedules of rest, time the performance of each activity and also maintain order, always seeking to optimize the hand of work.

Do not stop now... There's more after the advertising ;)

Read too: Work in the Third Industrial Revolution

Taylorism Innovations

Taylor developed some works aimed at business administration seeking the efficiency of the production system. One of his greatest legacies was "Principles of Scientific Administration", a book that basically exposes Taylor's belief in the rationalization of work. In this work, published in 1911, Taylor presented fundamental principles to Scientific Administration, which should guide the industrial administration model. There are four fundamental principles:

Planning principle: It was necessary to substitute improvised methods that considered the workers' individual judgments by scientific and planned methods, aiming at a better organization of work.

Principle of preparation of workers: It was necessary to select the workers according to their aptitudes and, thus, improve them through training, seeking a more efficient execution of tasks.

Control principle: It was up to the managers to control the work performed by the workers, keeping to time, avoiding waste and idleness.

Principle of execution: Distribution of responsibilities and functions of each worker in order to keep production under control and workers disciplined.

Read too: Labor relations and society

Criticism of Taylorism

Taylor's ideas, despite bringing greater productivity and increased profits for employers and advantages as well to the workers, such as the reduction of the working hours and higher wages, brought to light several discussions regarding the worker exploitation and mechanization, since the activities carried out became simple and repetitive.

The restriction to a single function made many workers feel robotized and alien to the production system. Workers began to question their functions and believe that this new form of organization benefited only employers, making them machines of the production system, therefore, disposable and replaceable. The workers' ideas were repressed and it was only up to the management to make decisions regarding production, which also generated discontent and conflicts between employees and employers.

Read too: Third Industrial Revolution

Differences between Taylorism, Fordism and Toyotism

The observations made by Taylor served as inspiration for some modes of organization of industrial production, such as the one proposed by Henry Ford, known as Fordism, and the toyotism, proposed by Taiichi Ohat the. See the main differences between these organization systems:

Taylorism |

Fordism |

Toyotism |

Mass production |

Mass production |

Batch production |

The work is carried out according to the income of each worker, so it was necessary to optimize it. |

The work is carried out according to the efficiency of the machines and belts installed in the factories. |

The work is carried out according to consumer demand. |

Existence of large stocks |

Existence of large stocks |

Stocks are not made. |

Production aims at the lowest possible time and expense. |

Production aims at the lowest possible time and expense. |

Production aims to meet demand. |

Quality control is carried out at the end of the production process. |

Quality control is carried out at the end of the production process. |

Quality control is carried out throughout the production process. |

Each worker has a single function. |

Each worker has a single function. |

Each worker performs different functions, and teamwork is a relevant factor. |

The work in its entirety is subordinate to management. |

The work is partially subordinate to management. |

Management supervises the work in a structural way, giving greater autonomy to the worker. |

By Rafaela Sousa

Geography teacher